Green energy-saving blow molding skills

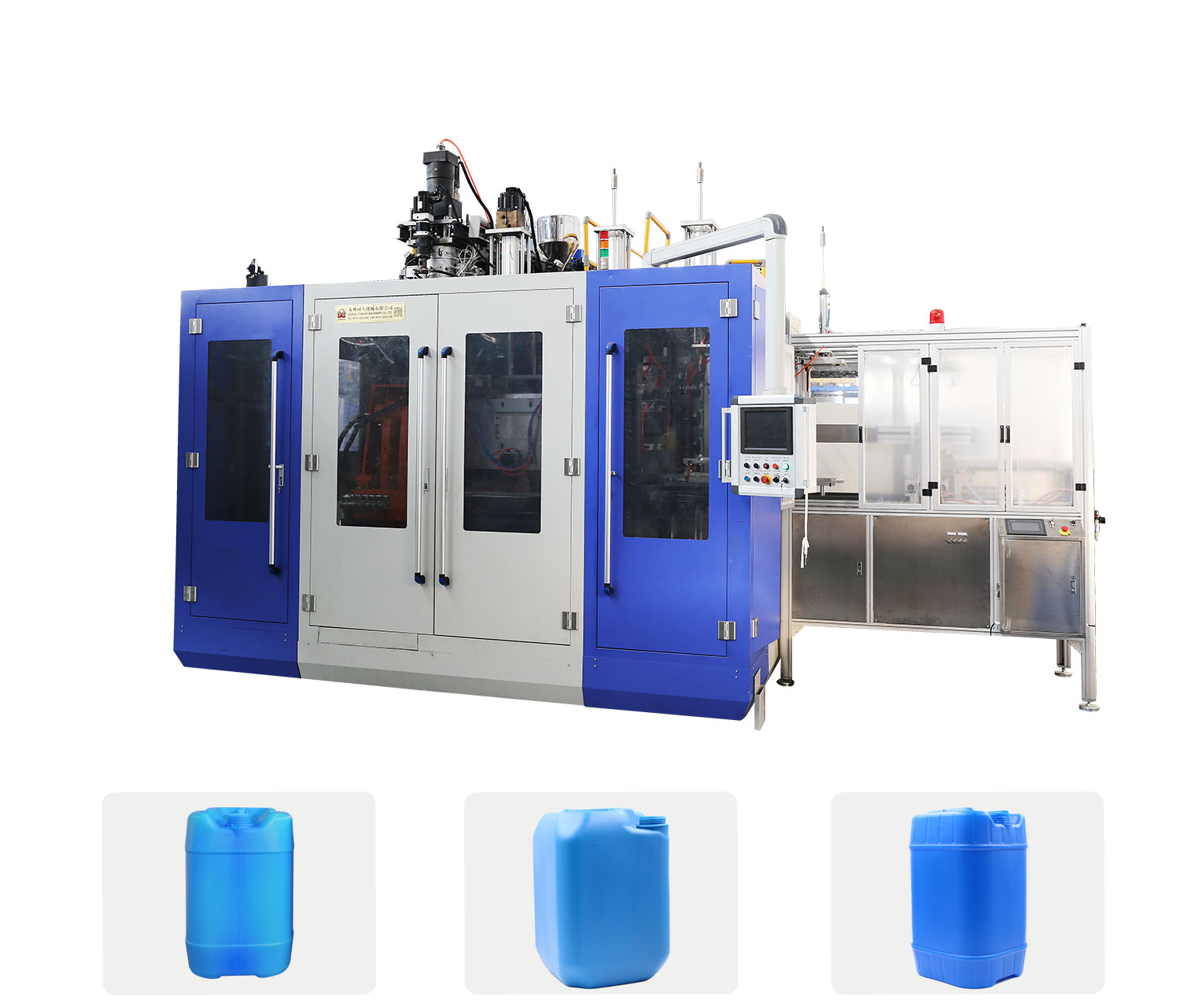

As a kind of plastic product manufacturer, the blow molding machine sprays out the liquid plastic and uses the wind generated by the machine equipment to blow the sprayed plastic onto the cavity of a specific trait and cool it to form the product to be produced. Greatly improved production efficiency. But we all know that the raw material of the blow molding machine is plastic, and it consumes electricity when it is working. Tongda extrusion blow molding machine actively carries out product innovation. On the basis of completing the basic functions of the blow molding machine, it strives to reduce energy consumption and produce energy-saving blow molding machines.

Let’s take a look at how the energy-saving blow molding machine is realized! There are two parts of the energy-saving blow molding machine, the power part and the heating part. The main function of the power part is to generate wind power. It uses the frequency converter to save energy. Usually it will save the remaining energy of the motor and change the power of the motor through the inverter to adjust the input power to the power required by the motor, just like the air conditioner. Inverter air conditioner. The modification of the blower to the blower makes the current of the motor many times higher than the rated current, which will affect the service life of the motor in the long run.

Another implementation part is the heating part, which is mainly used to heat the plastic into a liquid. Generally, the electromagnetic heater is used for energy saving. The electromagnetic heater increases the utilization rate of the heat energy by increasing the heat insulation layer, and at the same time, it can directly heat the material tube to reduce the The heat energy loss caused by the transfer of heat energy, while its heating speed is fast, and the production efficiency is improved. It saves 30% to 70% of electrical energy over older resistor rings.

Professionals from Suzhou Tongda remind everyone to pay attention to some plastic products made from recycled caps through recycled plastic granulators. It is recommended that you use less colorful plastic products, especially plastic bags, because of their usual origin. Unknown, chemical ingredients may cause harm to your health. Be sure to be alert to the irresponsible behavior of some unscrupulous merchants. When choosing a blow molding machine and plastic products, choose qualified manufacturers and better quality products, and try to buy energy-saving blow molding machines.