Plastic Blow Molding Equipment From Tongda

Within the realm of blow molding machines, there exist four prominent categories, each with distinct operational mechanisms and application domains:

- Hydraulic blow molding machine

- Servo blow molding machine

- Fully electric blow molding machine

- Other series

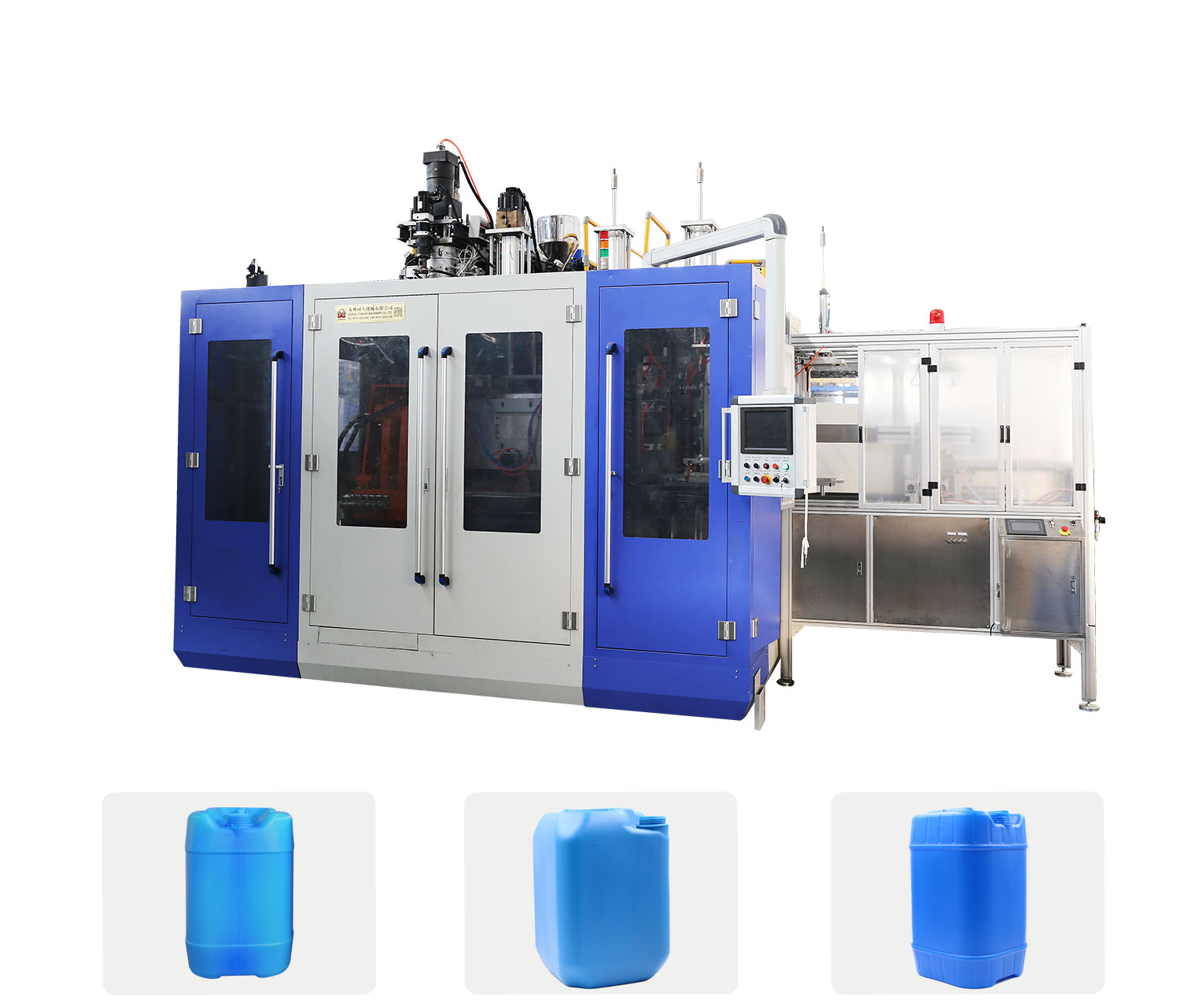

Hydraulic blow molding machine

Employing hydraulic systems for power and control, these machines offer high torque and force, ideal for manufacturing larger-sized plastic products or those requiring greater power.

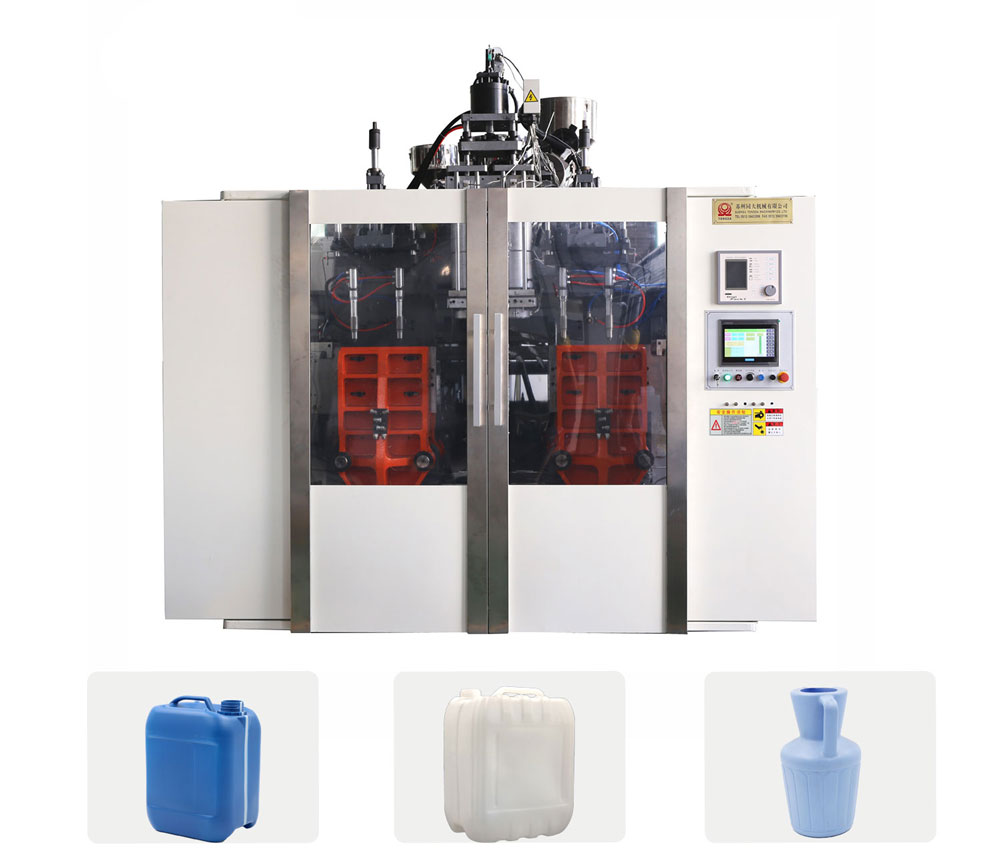

Servo Blow Molding Machines

Utilizing servo motors for propulsion and regulation, these machines deliver precise control and smooth motion, catering to applications demanding high precision and rapid production.

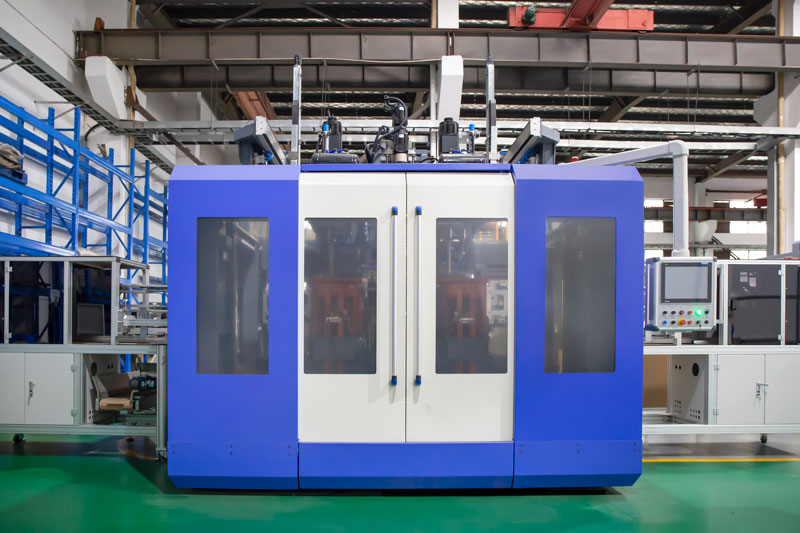

Fully-Electric Blow Molding Machines

Operating solely on electric drives without reliance on hydraulic or pneumatic systems, these machines often boast higher energy efficiency and lower maintenance costs, providing enhanced accuracy and control in specific applications.

Specialized Blow Molding Machines

This category encompasses customized or specially designed machines tailored for specific shapes, materials, or unique manufacturing processes. They might incorporate varied power systems, control mechanisms, or specialized processes to meet distinct production demands.

These diverse types of blow molding machines play pivotal roles within the plastic manufacturing industry, each offering unique advantages and suitability based on production requirements and product specifications.