Do the following five points to produce high-quality blow-molded pallets

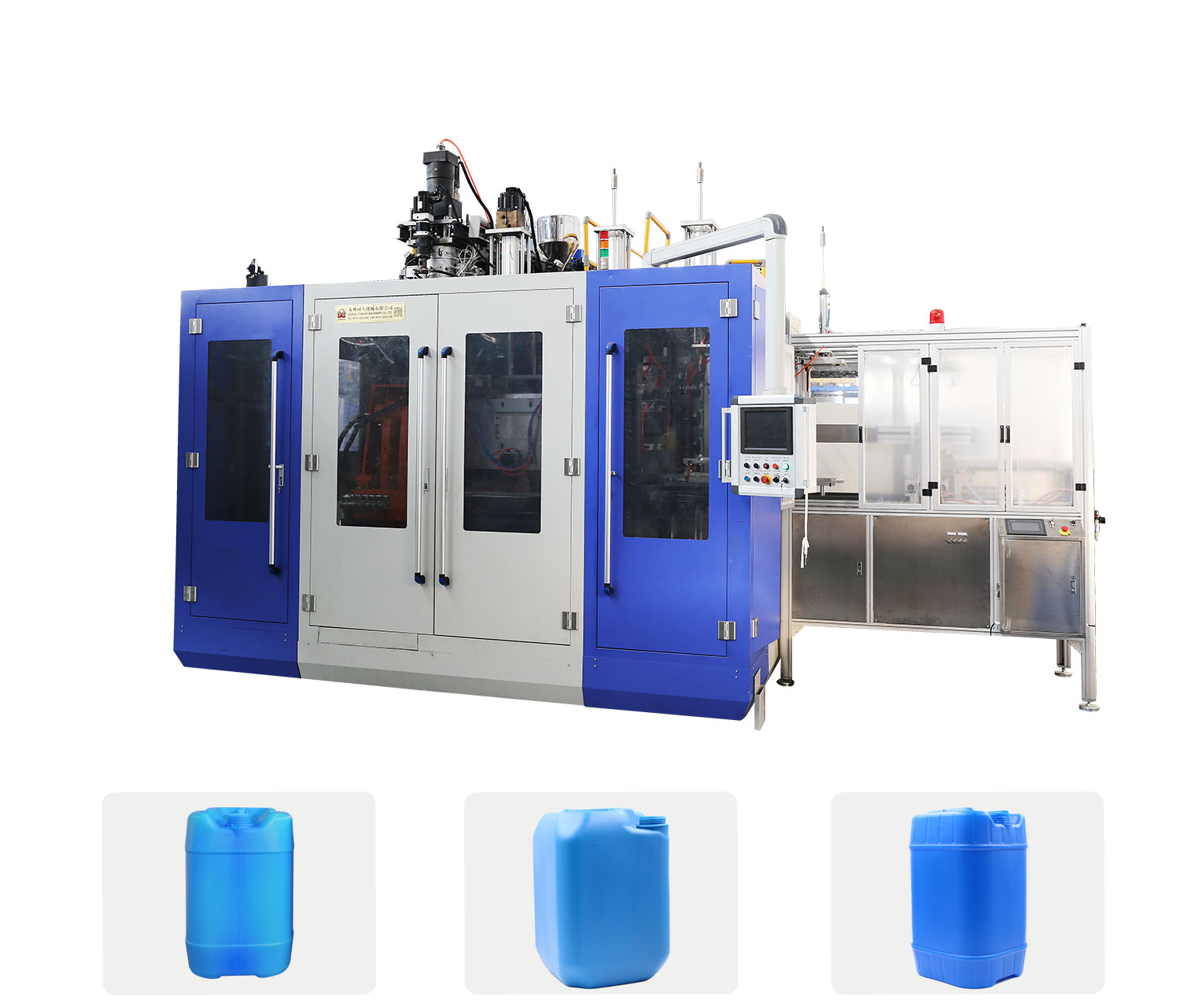

The following is about the application introduction of Tongda plastic pallet blow molding machine

1. The expansion of the mold and the die head: design the size of the die according to the width of the die, and use the time setting function of the die encapsulation and blowing to inflate the blank to a suitable size. The proportion of edges is small, and a good blow pallet is made while reducing the energy consumption of crushing flash.

Stable product process production: Set the appropriate molding process time, hydraulic pressure and flow rate, molding blow & cooling water pressure and flow rate, wall thickness controller graphics, and injection length according to the shape of the product.

Stable product process production: Set the appropriate molding process time, hydraulic pressure and flow rate, molding blow & cooling water pressure and flow rate, wall thickness controller graphics, and injection length according to the shape of the product.

2. Choose the right formula plastic: blow-molded blow pallets follow the high-density polyethylene (HDPE) plastic as an example, and select materials according to the characteristics of the products produced to make impact-resistant, pressure-resistant, and crack-resistant trays, while reducing material costs.

3. According to the characteristics of the plastic, the polymer screw design screw can be divided into high plasticization capacity type, color mixing uniformity and high yield and high color mixing type double alloy screw.At this time, the appropriate screw can be selected according to the characteristics of the product.

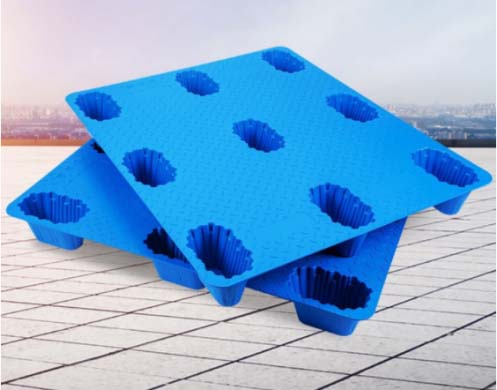

4. Mould design such as double-sided blow pallet and nine-foot pallet:

When designing the mold, a reasonable angle must be considered to avoid the product being unqualified due to excessive product pull.Reinforcing ribs are the prerequisite for the quality of the blow pallet. The strength of the product depends on the strength and quantity of the reinforcing ribs, which should be increased as much as possible during the design.

5.The ratio of the product’s scraps for recycling should be reasonable: add the ratio of the mixed recycled scraps and new materials, and determine the ratio according to the results of the test. When using the mixture to make the product, it needs to be stirred evenly, too much, too little Will affect the quality of the product.