How to choose the right extrusion blow molding machine

Nowadays, there are many manufacturers of extrusion blow molding machines in China, which are mixed and varied. How to choose the right blow molding machine is not important. There are many practical traps for selling extrusion blow molding machines. Some have bought hollow blow molding machines and thought they are cheaper. In fact, it is not the case. There are many troubles in the future.

Before choosing a blow molding machine, you must first analyze your own products and products that you need to do in the future to choose a product that suits you. For example, analyze the weight, size and requirements of the product, and what material. The size of the weight determines the size of the device, whether it is done with a multi-die or with a multi-station multi-die. If the product has more than four hundred and five hundred grams, you may want to choose more than 75 fixed and open molds. For small machines, consider the size of the opening and closing mold, the stability of the mold, and the stability of the position of the needle. If these changes frequently, it will affect the quality and efficiency of the product. Some customers spend very cheap money on equipment to buy back, and the result is arranging. The reason is very unstable, people need to keep watching, keep on adjusting, time-consuming and laborious. The small machine depends on the configuration and material, as well as the rationality of the design. Generally, the small machine is relatively standard, and there are fewer optional parts.

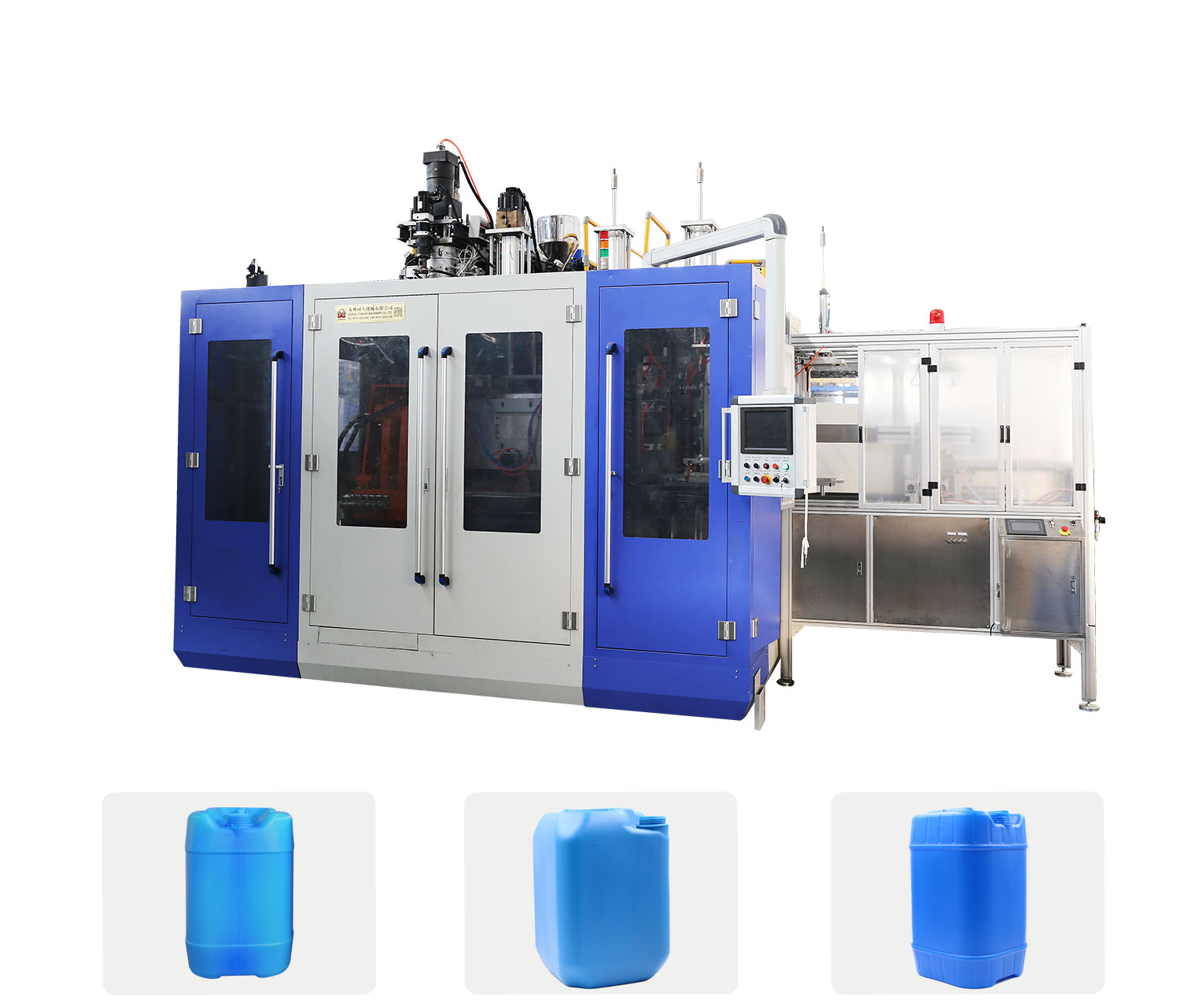

Extrusion blow molding machine

More than 75 large machines can be selected, such as blowing, manipulator, wall thickness controller, etc. The configuration is also good or bad. The same model has some people with small motors, the products in front of you can do, once there is a little larger product, it is not good. Some manufacturers such as 120 are cheaper, but the motor is only 90KW. Of course, it can be done, but it will affect the plastic force. What is not seen is the clamping force. It is also a 90 machine, and some of the clamping force is too small. Wall thickness controllers are currently available in China, B&R, and Japan’s MOOG, and some are low cost in PLC. The best use is the Japanese MOOG wall thickness controller, the price will be slightly higher.

Energy saving is also very important in today’s era. The cost of electricity directly affects the cost of the product. At present, there is no good energy-saving method for small machines. The energy saving of large machines is more. The twisting materials are variable frequency materials. Our main consideration is the oil pump. At present, there are three forms: 1, energy storage of energy storage; 2, energy saving by frequency conversion; 3, servo energy saving; of course, the best effect is servo energy saving, and the cost will be relatively higher. If you choose domestic servos, it will be cheaper. If you use imported, the cost will be higher.

In short, the choice of equipment must be practical. I wish you a choice of products that you like.